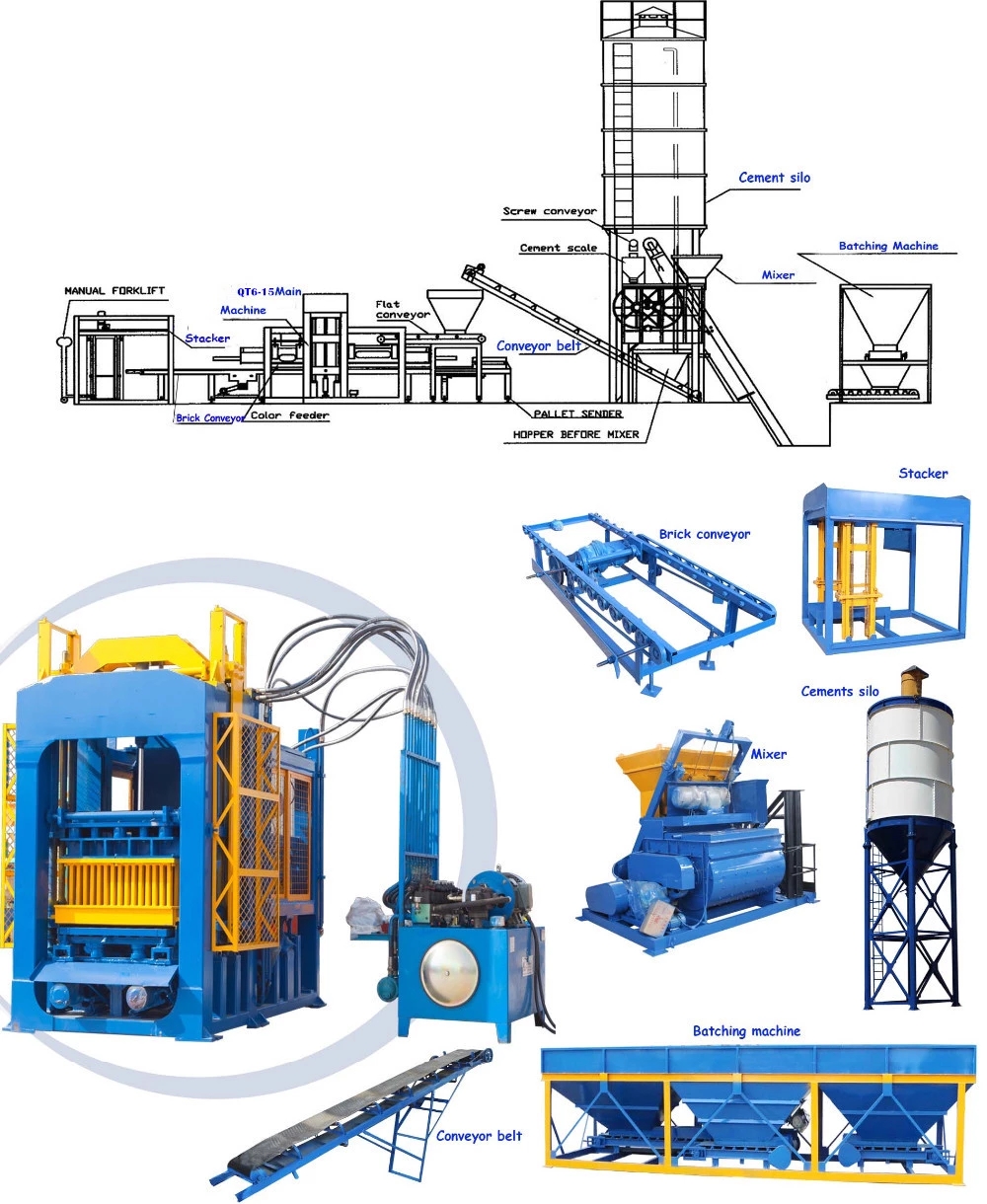

QT6-15 Automatic Hydraulic Making Machine

1- QT6-15 Fully Automatic Stacking Brick Making Machine Plant use PLC intelligent control, make the man-machine interface as true, control system equipped with complete logic control, production program, malfunction diagnosis system and remote control function.

2- Can produce the paver block with or without color on the surface, if need color, should use the face-color material feeding device.

3- Through mold-releasing oil cylinder, the mold box was locked into the vibration table with high rigidity to reach the synchronous vibration, so that the concrete can be fluidified and exhausted in two or three seconds to ensure the high-density,especially suitable to produce the standard blocks, which can be piled up immediately so that the pallet investment can be saved directly.

4- The unique forcing charge system can make use of various kinds of industrial waste and material such as coal ash, cement, sand,stone, slag, and so on. The machine can severs several purposes and produce various specification standard bricks, concrete blocks, porous blocks, paving bricks etc just changing the mold.

Technical Specification

| Power | 36.4KW |

| Cycle | 15-18(s) |

| Vibration Force | 88KN |

| Rated Pressure | 21Mpa |

| Pallet Size | 900*680*25mm |

| Machine Size | 3800*2000*2510mm |

| Land Area | Shaded Area:600-800M2 |

| Stoking Area:2500-3000m2 | |

| Worker | 5-7 Workers |

| Related Accessories | 50T Silo,PLD1200 Batching Machine.JS750 mixer,Forklift,2000pcs Pallet |

Production Capacity

| spec | Hollow Block | Hollow Block | Rectangular | “I”Shape | “S”Paver | Porous Brick | Solid Brick |

| 400*200*200 | 400*100*200 | 200*100*60 | 200*165*60 | 225*112.5*60 | 240*115*90 | 240*115*53 | |

| Photo |  |

|

|

|

|

|

|

| Pcs/Pallet | 6 | 12 | 21 | 12 | 15 | 15 | 30 |

| Pcs/Hour | 1080 | 2160 | 3780 | 2160 | 2700 | 2700 | 5400 |

| Pcs/8 Hour | 8640 | 17280 | 30240 | 17280 | 21600 | 21600 | 43200 |

| 1 year(300 days) | 36507m3 | 38400m3 | 181440m2 | 171089m2 | 164051m2 | 6.48million pcs | 13million pcs |

Product details

Product Description

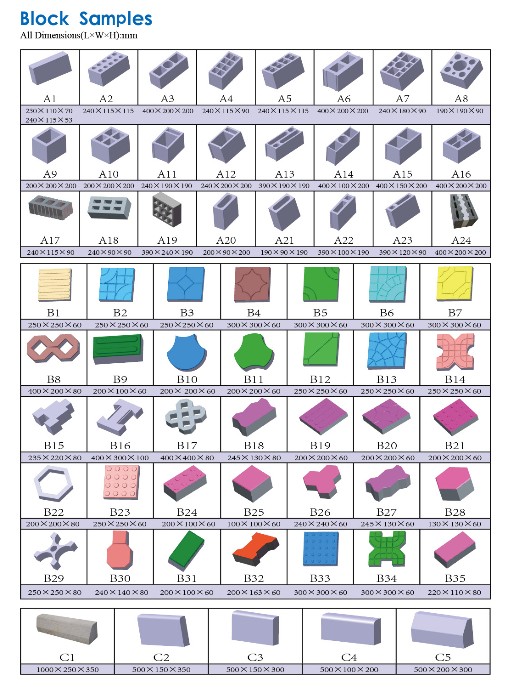

1)Full automatic block paver brick block making machine can produce various solid blocks , hollow blocks, pavers and curbstones bychanging moulds.

2) Adopt Japan Omron and France Schneider brand switches, Siemens and ABB brand motors to make high quality machinery.

3) Precise line cutting technology and carburizing treatment technology to prolong mould life and increase precision of the block.

4) Reasonable raw material ratio can produce high strength standard brick, after forming, can stack immediately.

5)The PLC control system made by Japan Mitsubishi brand,assure stable and high efficiency working status.

Packing & Delivery