QT5-15 Automatic Hydraulic Block Making Machine

Our QT5-15 production line starts with a batching machine that weighs the raw material (sand, crushed stone and other materials)according to the customer desires ratio. Then it transfer the materials to the mixer hopper.

The mixer hopper automatically transfers the material into the mixer to make the correct formulation. After being mixed it is poured onto the conveyor system that sends it to the block pressing machine.

The block pressing machine vibrates the mixture into the desired mold and sends out the finished block on the other end on the PVC pallets. After this it is sent to the stacker which takes the finished blocks and stacks them to be moved around the drying yard with a forklift.

All this is operated by the main control panel on the opposite side of the production line and all operational equipment has safety wire screening to protect the workers. The machines comes with three different size molds and 1000 PVC pallets.

Techincal Specification

| Power | 28.65KW |

| Cycle | 15-18(s) |

| Vibration Force | 80KN |

| Rated Pressure | 16Mpa |

| Pallet Size | 1100*550*25mm |

| Machine Size | 3700*170*2550mm |

| Land Area | Shaded Area:600-800M2 |

| Stoking Area:2500-3000m2 | |

| Worker | 5-7 Workers |

| Related Accessories | PLD800 Batching Machine,JS500 mixer,2000pcs pallet |

Production Capacity

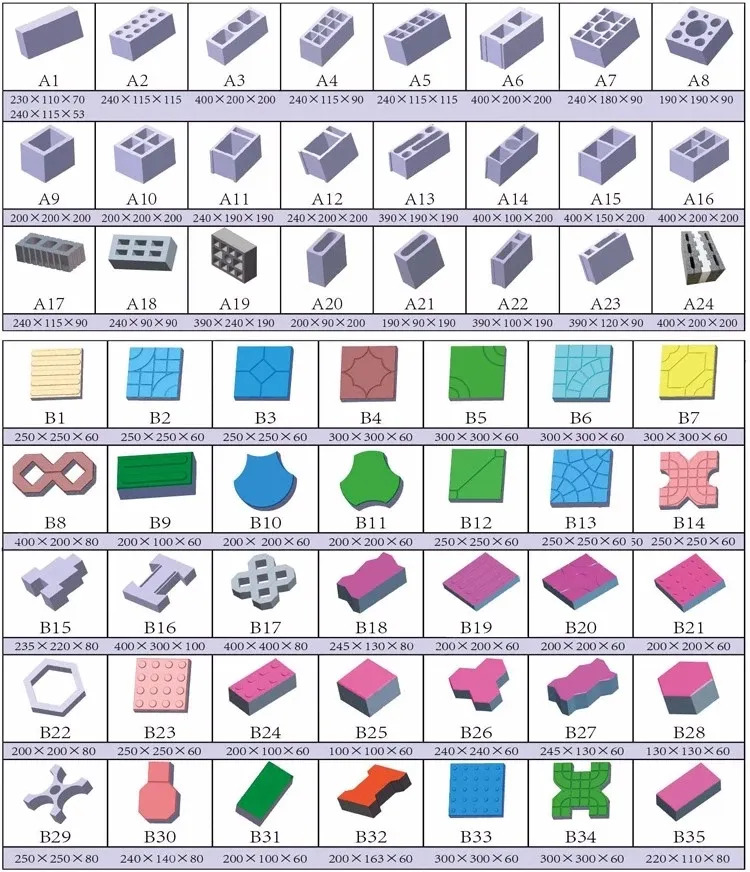

| spec | Hollow Block | Hollow Block | Rectangular | “I”Shape | “S”Paver | Porous Brick | Solid Brick | Hourdis |

| 400*200*200 | 400*100*200 | 200*100*60 | 200*165*60 | 225*112.5*60 | 240*115*90 | 240*115*53 | 500*150*200 | |

| Photo |  |

|

|

|

|

|

|

|

| Pcs/Pallet | 5 | 10 | 20 | 10 | 16 | 16 | 34 | 6 |

| Pcs/Hour | 900 | 1800 | 3600 | 1800 | 2880 | 2880 | 6120 | 1440 |

| Pcs/8 Hour | 7200 | 14400 | 28800 | 14400 | 23040 | 23040 | 48960 | 11520 |

| 1 year(300 days) | 30423m3 | 32000m3 | 172800m2 | 142574m2 | 174987m2 | 6.91million pcs | 15million pcs | 51840m3 |

Product details

1- QTA5-2000 Fully Automatic Stacking Brick Making Machine Plant use PLC intelligent control.