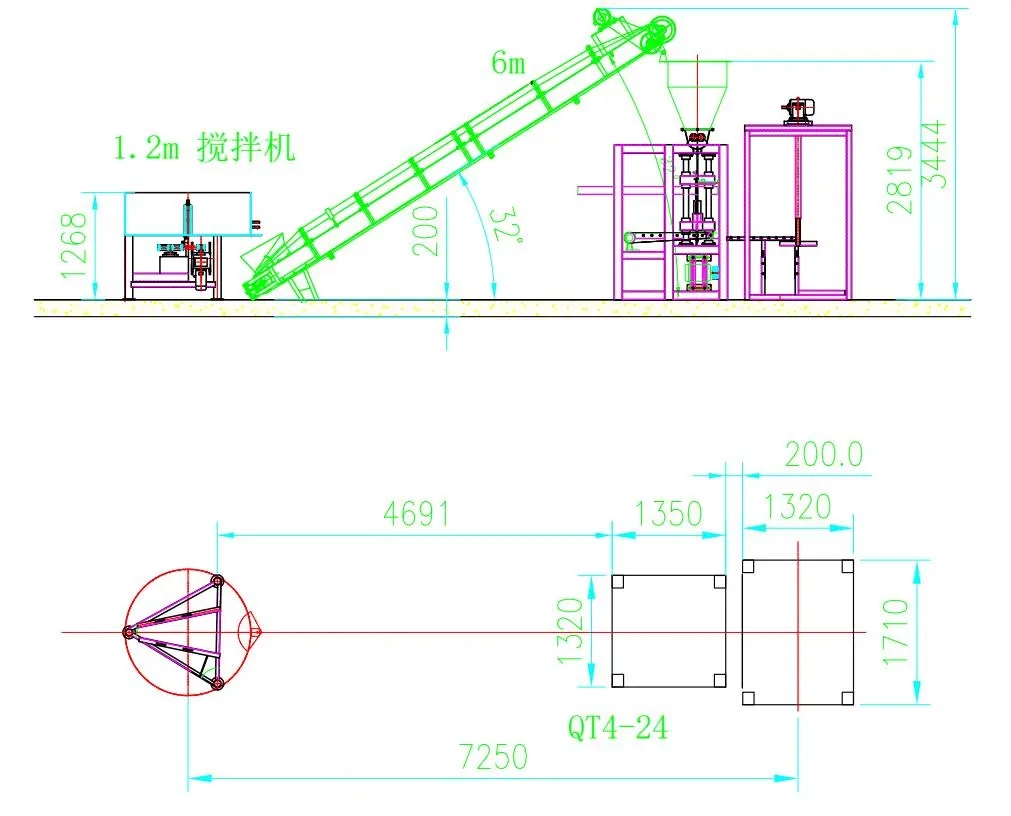

QTJ4-26C Semi Automatic Block Making Machine

Technical Specification

| Power | 11.75KW |

| Cycle | 20-26(s) |

| Vibration Force | 22KN |

| Pallet Size | 850*550*20mm |

| Machine Size | 3000*1600*2500mm |

| Machine Weight | 3000KG |

| Land Area | Shaded Area:50-100m2 |

| Stoking Area:600-1500m2 | |

| Worker | 4-5 Workers |

| Related Accessories | JQ500 Mixer and 700PCS Pallet |

Production Capacity

| spec | Hollow Block | Hollow Block | Rectangular | “I”Shape | “S”Paver | Porous Brick | Solid Brick |

| 400*200*200 | 400*100*200 | 200*100*60 | 200*165*60 | 225*112.5*60 | 240*115*90 | 240*115*53 | |

| Photo |  |

|

|

|

|

|

|

| Pcs/Pallet | 4 | 6 | 16 | 12 | 12 | 9 | 21 |

| Pcs/Hour | 480 | 720 | 1920 | 1440 | 1440 | 1080 | 2520 |

| Pcs/8 Hour | 3840 | 5760 | 15360 | 11520 | 11520 | 8640 | 20160 |

Product Description

Product performance description

1) The whole machine adopts PLC system and computer interface operation ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3)Increase the effective work surface: The application of new vibration technology makes the machine have a large work surface, which greatly improves the production efficiency.

4) Running in a high automatization and intellectualization,no pollution 5) It can produce fly ash bricks or blocks with 80% fly ash content, and it is free from steaming. It is naturally dried under normal temperature and pressure conditions.

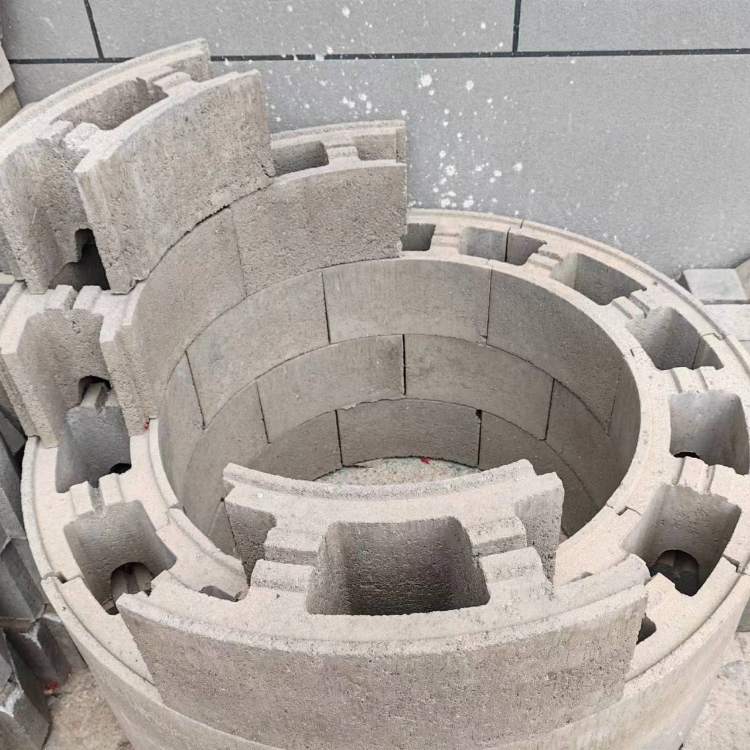

Finished product display and application

1.Our block machine is one of our newly designed block making machine with less power.

2.It adopts full automatic spiral material laying method, so the material in the mould is well-distributed. With simple operation and high productivity, when producing hollow blocks, it has an advantage over the large hydraulic block machines.

3.It uses Mode 350 speed reducer to raise and lower the mold, so it greatly increases the usage life of the speed reducer.

4.The blocks made by this machine has high strength and accurate size.Its performance and product quality are comparable to the large equipment.

Packaging&Shipping

Packaging:

First, wrap the mechanical equipment with plastic wrap, and then put the wrapped mechanical equipment into the wooden box after packaging.

Shipping:

First by truck to the port, and then by sea to the destination.